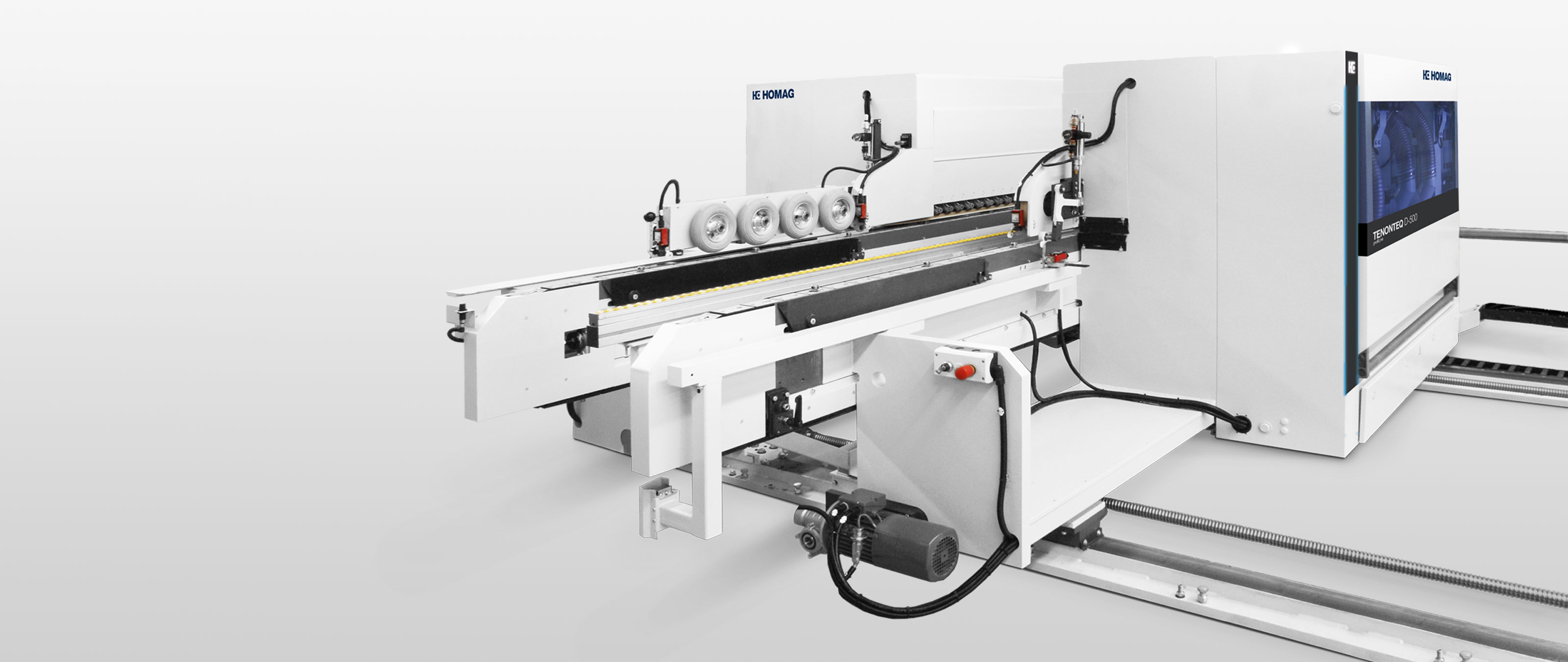

Double End Tenoners TENONTEQ D-500

Double End Tenoners TENONTEQ D-500

A compact introductory solution for double-sided dimensioning work

This high-performance double-end profiler can be configured as required to tackle a host of different tasks: angle cuts, bevel cuts, profiling, rabbeting, grooving, sanding and corner processing. Thanks to its robust design, low-wear technology and high level of availability, this machine is exactly the right choice for manufacturing doors, fronts and panels.

Benefits

Images

Features

-

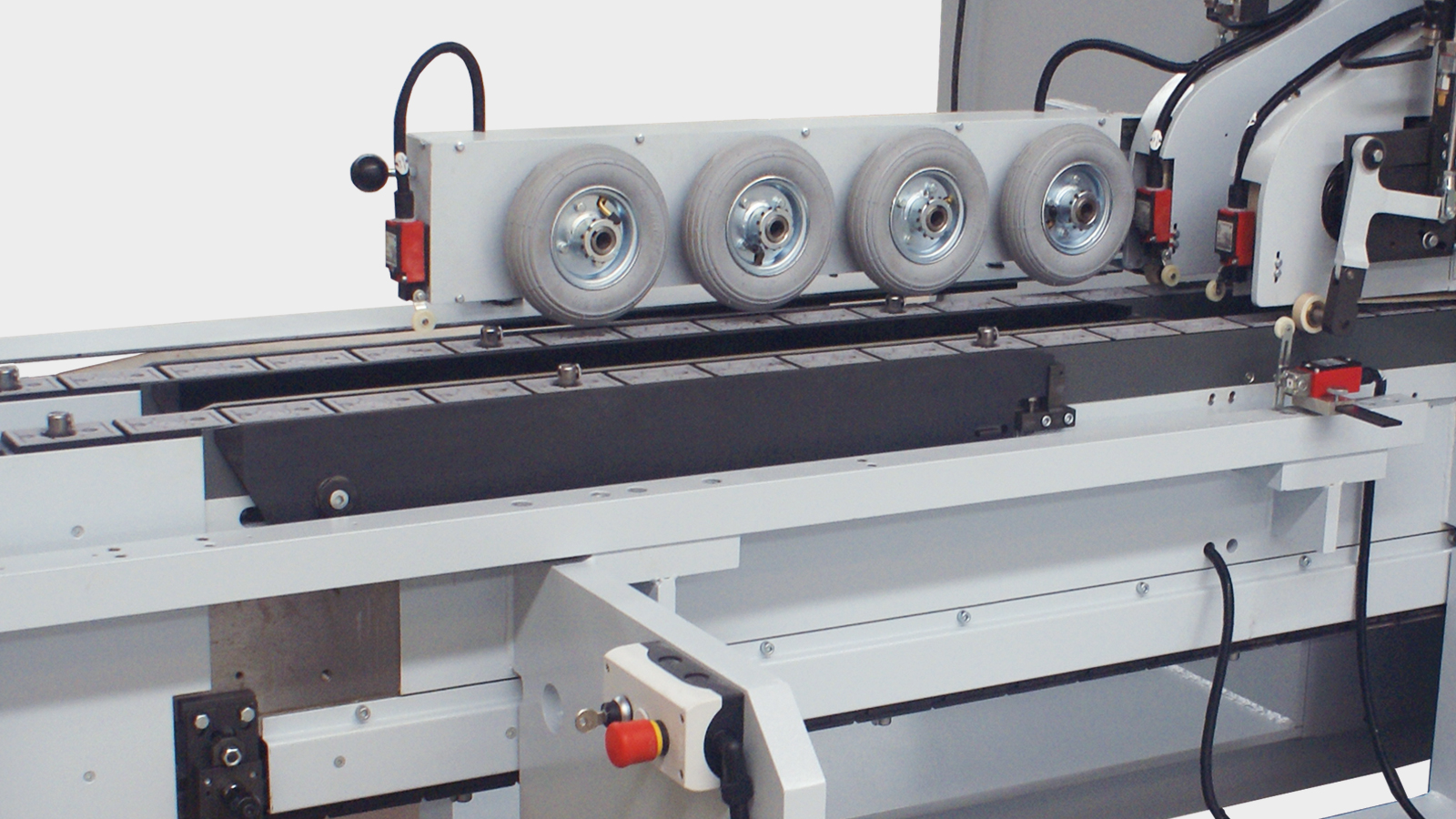

Scoring and chipping unit for tear-free processing of coated surfaces or clean cross processing of veneered parts and solid wood

-

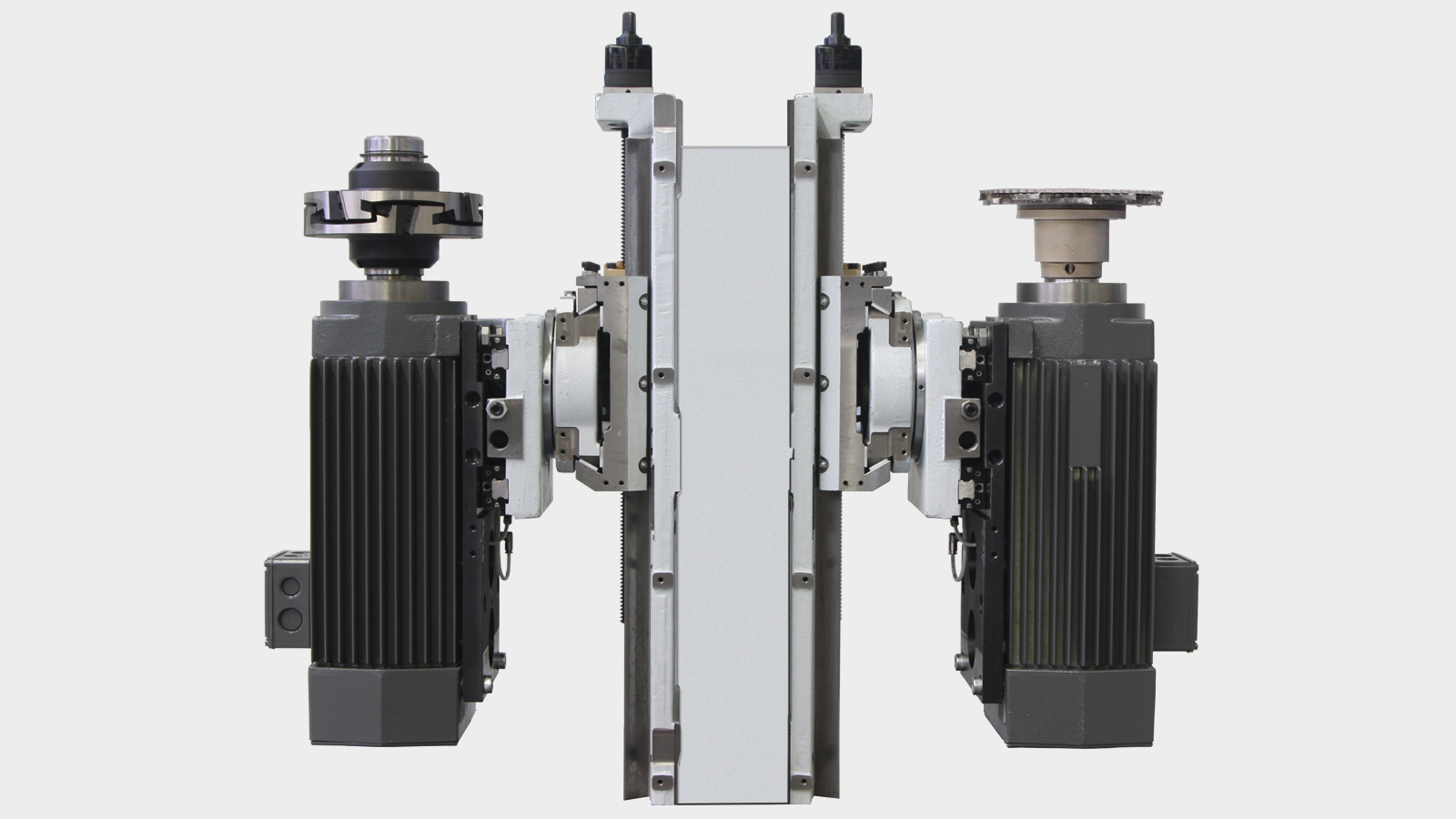

SF20 standard trimming unit for trimming, rabbeting, profiling, grooving etc., electro-pneumatic control system, swivel range of 90° and reversing switch for controlling the direction of rotation of tools

-

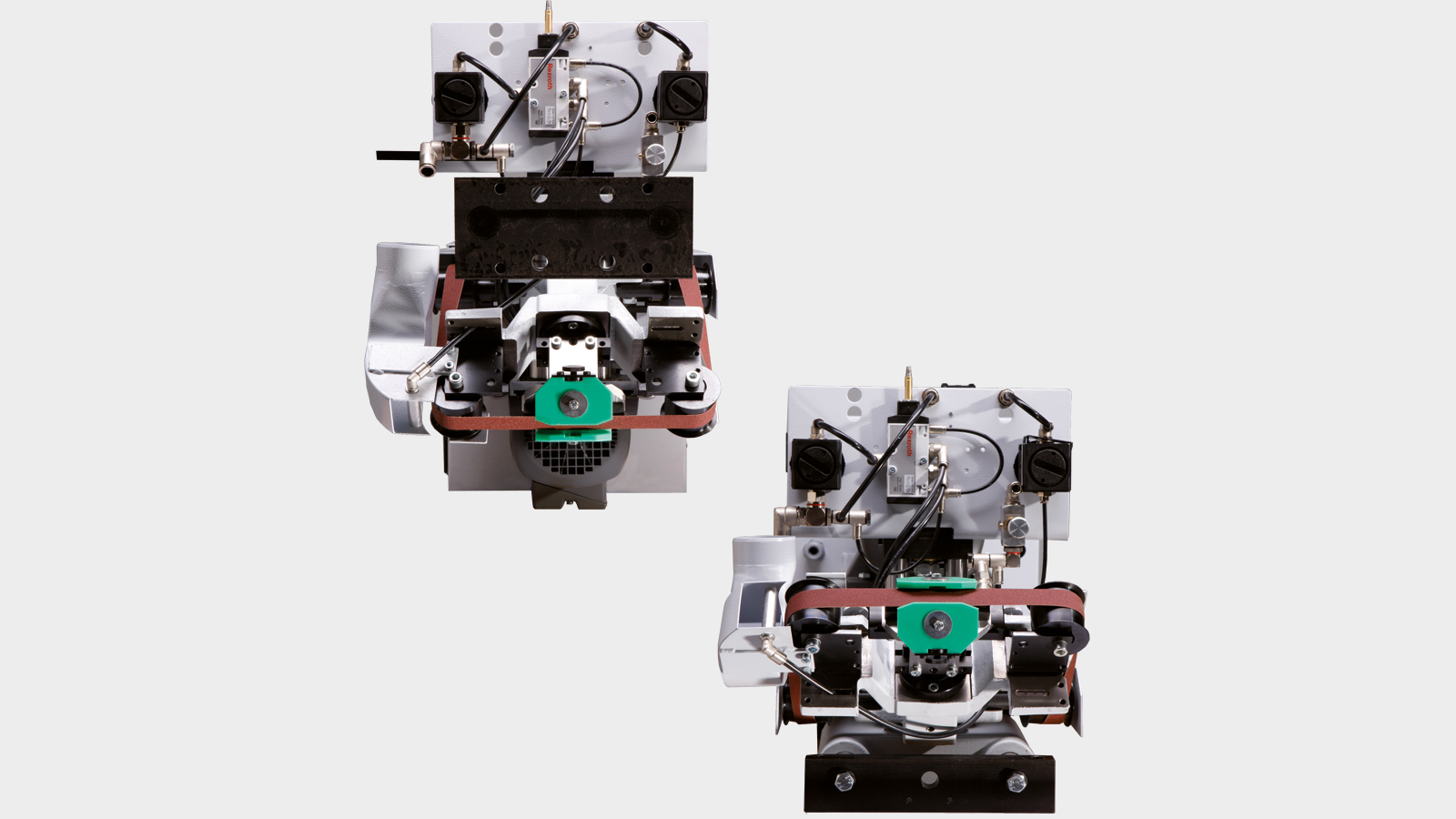

KS10 belt sanding unit with vertical oscillation for even sanding of straight edges and to enable optimum belt utilization

-

PS20 belt sanding unit with a belt length of 3200 mm and the option to sand special profiles using two separate, individually adjustable sanding pads (dual sanding pad Technology)

Technical Data

| TENONTEQ D-500 | ||

|---|---|---|

| Overall length [mm] | ||

| FPL 265 | 3,650–5,650 | |

| FPL 266 | individual machine | 4,650–6,650 |

| FPL 266 | Line execution | 4,880–6,880 |

(Previous product name: Double-End Tenoner FPL 260: for furniture production and interior furnishings)